Manufacturing isn’t always the first industry associated with digital innovation, but that’s changing fast. Once seen as a traditional sector slow to evolve, manufacturing is now embracing AI business solutions and becoming a more agile, data driven company. This shift is transforming how manufacturers operate, make decisions, and compete in an increasingly digital economy.

According to Meghan Cipperley, Senior Vice President of Learning at Data Society:

Manufacturers are realizing that without high-quality, structured data, they can’t fully leverage AI business solutions, optimize operations, or improve decision-making. Data is no longer a byproduct, it’s a strategic asset. Companies that invest in data literacy and training, such as a tailored artificial intelligence and data science course, position themselves as true data driven companies, ready to lead the industry’s digital transformation.

Why Manufacturing is Investing in Data Training

Historically, manufacturing has lagged behind industries like finance, healthcare, and tech in adopting data-driven processes. But that’s beginning to shift as more manufacturers turn to AI business solutions and prioritize becoming a data driven company. With the right strategy and a custom course designed for their unique needs, manufacturing teams can catch up, and even leap ahead, in digital capability and performance. However, that is changing due to:

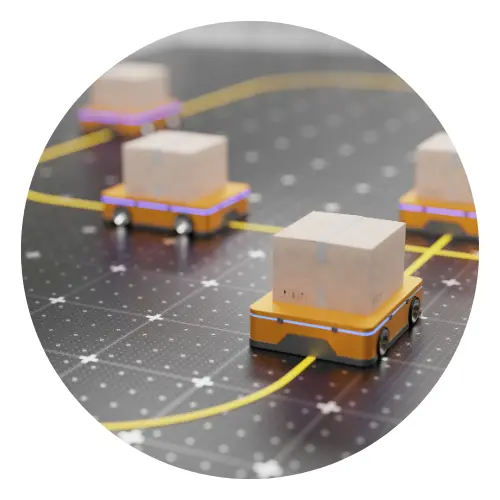

- The Rise of Industrial AI & Automation: Manufacturers are integrating AI into their supply chains, but these systems require accurate and structured data to function properly (World Economic Forum).

- Demand for Real-Time Analytics: Companies are leveraging predictive analytics to optimize maintenance schedules, reduce downtime, and improve efficiency (McKinsey & Company).

- Workforce Digital Upskilling: As frontline workers interact with more technology-driven systems, they need foundational data literacy to make informed decisions and ensure operations run smoothly.

Meghan Cipperley explains:

“If you don’t have the data, you cannot train your large language model.”

She continues:

“Frontline workers are asking how they can contribute to a data-driven culture. Leaders are recognizing that data literacy isn’t just for analysts. It must be embedded across the workforce.”

The Biggest Challenge: Data Readiness

Many manufacturing companies understand the importance of data but often face challenges with data quality, accessibility, and workforce readiness. To address these gaps, forward-thinking organizations are turning to AI business solutions paired with targeted training. A custom course, especially an artificial intelligence and data science course tailored to manufacturing, can equip teams with the skills they need to manage and apply data effectively. It’s a crucial step toward becoming a truly data driven company.

Without proper data governance and literacy programs, AI adoption remains a challenge. As recommended by dataPARC: “Manufacturers need to assess their current data ecosystems to identify gaps and areas for improvement before diving into artificial intelligence. […] It includes fostering a culture that embraces data-driven decision-making and encourages continuous data utilization and integration.”

To bridge this gap, companies must:

Invest in Data Literacy Training Across All Levels

- Employees should understand how to collect, analyze, and apply data to make data-driven decisions.

- Training should not be limited to analysts and engineers but should include production managers, technicians, and frontline staff.

Ensure AI Investments Have a Clear ROI

- AI should be used to solve real operational challenges, not just as a tech trend.

- Companies should measure how AI adoption improves efficiency, reduces costs, and enhances productivity.

Empower Employees to Work with AI & Analytics Tools

- Workers need training that helps them interpret and use AI-powered insights, ensuring that new technology aligns with day-to-day operations.

Final Thoughts

Manufacturing is poised for a quiet data revolution, and companies that invest in AI business solutions and data literacy now will gain a lasting competitive edge. In the era of the Fourth Industrial Revolution, the ability to make data-informed decisions and deploy smart technologies sets industry leaders apart. A strategic investment in a custom course or a focused artificial intelligence and data science course can accelerate this shift, helping manufacturers become the kind of data driven company that thrives in a rapidly evolving landscape.

If your organization is looking to build a data-driven workforce and maximize AI adoption, Data Society can help.

Contact Data Society today to learn how we can develop a customized data training program for your team.